Saving energy with electronic water conditioners

A water conditioner is an equipment that reduces the effects of hard water in terms of the build-up that is left on the surfaces the water comes into contact with. Hard water can clog up pipes and force your equipment to work much harder than it needs to. Electronic water conditioners use a magnetic field to induce energy to the minerals which pass through it. As the water flows, these minerals take on a different crystalline structure form when precipitated. It develops an increased solubility factor which helps it absorb more of whatever the water may be mixed with downstream.

The Chemistry behind it:

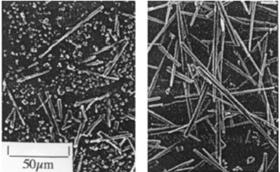

Calcium carbonate (the major component of the build-up) exists in two crystal forms: aragonite and calcite. Aragonite has an elongated structure, Brinell hardness of 3.5 – 4, and density of 2.95. Calcite has a rhombohedral structure, Brinell hardness of 3, and density of 2.71. Where the opportunity occurs, ions, atoms, or molecules arrange themselves in positions of least energy and more symmetrical and regular crystal forms.

The magnetic field affects the intermolecular forces and, as a result, changes the crystalline structure of the build up from calcite to aragonite, as discussed above. This effect makes water more capable of dissolving the existing scale build-up encrustations which, in the form of “lime sludge,” can be easily rinsed away.

Aragonite transforms calcium ions into calcium crystals, which are stable and cannot attach to pipes, surfaces, hardware, or heat exchangers components. They are easily rinsed away by the water flow because the crystals are so small. Aragonite is a finer particle which is non-adherent to the inner walls of plumbing and fixtures. These particles form a talc-like powder which is soluble, allowing the nutrients to remain in your water in a bio-absorptive form.

These water de-scalers aid the industry in its pursuit for higher efficiency, and more ecologically acceptable water softening equipment. It is important to also note of the elements of the system and ensure adequate magnetic strength to achieve optimal results. For example, a pipe made of PVC will require less strength than one made out of cast iron.

Here is a List Studies that show results of the Electromagnetic Process and its success.

| 2018- Scaling in water supply networks can cause various problems. They are mainly due to the deposit of CaCO3 which can lead to damages of the water piping. For example, boiling processes in factories do not work well when they are fouled with these deposits. According to the team’s hypothesis, the nonreactive aragonite crystals will not attach on the vessel during the boiling procedure. | Alnashwan, A, et al. “Increased Calcite Nucleation (ICN) to Prevent Scaling in Boilers Researching an Alternative to Water Softeners.” Northern Arizona University |

| 2017- “The aragonite crystals can’t form scale because of its stable molecular structure and neutral surface electro potentiality.” Studies in China, US, Europe, India and Korea | “Technologies for the Removal of Water Hardness and Scaling Prevention.” Journal of Energy Engineering, vol. 26, |

| 2010: “Show the effects of different surfaces and their capabilities under MWT. Conditions need to be correct for effective treatment”. | “Surface Modification and Planar Defects of Calcium Carbonates by Magnetic Water Treatment”. Nanoscale Research Letters. |

| 2009: “Shows the effectiveness of descaling under Aragonite crystalline structure and its positive results in pipe flow”. | Effect of magnetic water treatment on calcium carbonate precipitation: Influence of the pipe material”. Chemical Engineering and Processing: Process Intensification. 48 (8): 1327 |

| “All alternative devices were effective at reducing scale. The most promising technology is the template assisted crystallization with scale reductions of over 90%”. | Evaluation of Alternatives to Domestic Ion Exchange Water Softeners; Mara Wiest Dr. Peter Fox Dr. Lee Wontae, HDR Tim Thomure, HDR |

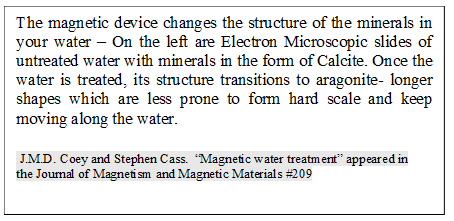

The table shown below shows the heat transfer effect that calcification can have on a chiller and cooling tower system. Notice that as the thickness of calcium increases the heat transfer coefficient is severely lowered.

To proof the effect shown above we decided to run a pilot test on a system that is condensed by air in Medellin, Colombia. In December 2020, an WEC-350 Water Conditioner, was installed to remove the calcification that had been accumulated for over 20 years in the pipes of the HVAC System of the Sheraton Four Points Medellin. Their chiller system had been replaced in 2019 by an LG high efficiency air cooled chiller with combined 70 tons capacity running 24/7. Weather in Medellin is very mild (72 F) all year round. We had a monitoring software installed taking measurements of the chiller Power consumption, temperatures entering and leaving the chiller and velocity of water flow. All those parameters were calculated into Power being consumed and tons of refrigeration being used (KW/ton) every hour and comparing it to guest occupancy.

Here is the data before and after for Sheraton Four Points Medellin:

Before the water conditioner was installed the system was averaging a consumption rate of IPLV (Integrated Partial Load Value) 0.64 KW/ton of refrigeration.

After the water conditioner was installed, it averaged 0.39 – 0.49 KW/ton depending on the chiller load which was a factor of hotel occupancy. Therefore, the water conditioner achieved at least a 23% energy savings just on the chiller side.

About the Authors:

Mr. Ivan R. Meneses, PE, CEM, EBCP is a Florida Licensed professional engineer with a Master’s degree in Construction & Facilities Management and 22 years of experience in HVAC and Energy Generation Field in government and commercial facilities. Mr Meneses is the CEO for a startup company that specializes in Energy and Water Savings technologies in the US and Latin America. His Master Thesis from GA Tech involved a Case Study to solve Indoor Humidity issues at a federal government housing complex. Mr. Meneses is also a Professional Engineer, a certified energy manager, Florida Mechanical Contractor and certified Existing Building Commissioning Professional.

Mr. Jose Arturo Luna, CEM is an Electrical Engineer with over 15 years of electrical design experience and over 20 years of experience in the management of energy efficiency projects in Latin America and the Caribbean; these successful projects include hotels from major hotel chains such as Marriott, Barceló, Sheraton, Sonesta. Mr. Jose Arturo Luna is a Certified Energy Manager and Member International II of the Association of Energy Engineers AEE USA.

Sources:

Ahn, Min Kyung, and Choon Han. “Technologies for the Removal of Water Hardness and Scaling Prevention.” Journal of Energy Engineering, vol. 26, no. 2, 2017, pp. 73–79., doi:10.5855/energy.2017.26.2.109.

Alnashwan, A, et al. “Increased Calcite Nucleation (ICN) to Prevent Scaling in Boilers Researching an Alternative to Water Softeners.” Northern Arizona University , 18 Dec. 2018.

Alimi, F.; Tlili, M. M.; Amor, M. B.; Maurin, G.; Gabrielli, C. (2009). “Effect of magnetic water treatment on calcium carbonate precipitation: Influence of the pipe material”. Chemical Engineering and Processing: Process Intensification. 48 (8): 1327

Coey, JMD; Cass, S (2000). “Magnetic water treatment” (PDF). Journal of Magnetism and Magnetic Materials. 209 (1–3): 71–74.

Coke, Alden L. “Magnetic Water Conditioners: Fact, Fiction or Unknown?” Water & Wastes Digest, 2000, www.wwdmag.com/magnetic-water-conditioners-fact-fiction-or-unknown.

Liu, C. Z.; Lin, C. H.; Yeh, M. S.; Chao, Y. M.; Shen, P (2010). “Surface Modification and Planar Defects of Calcium Carbonates by Magnetic Water Treatment”. Nanoscale Research Letters. 5 (12): 1982–1991